arrow_back_ios

See All Produkte

See All Wissen

See All Lösungen

See All Services & Support

Main Menu

arrow_back_ios

See All Software

See All Instrumente

See All Aufnehmer

See All Schwingungsprüfung

See All Elektroakustisch

See All Akustische End-of-Line-Testsysteme

See All Events

See All Akademie

See All Anwendungen

See All Industrien

See All Kalibrierung

See All Ingenieurdienstleistungen

See All Unterstützen

Main Menu

- Akustik

- Strom und Spannung

- Weg

- Kraft

- Wägezellen

- Mehrkomponenten

- Druck

- Dehnung

- Dehnungsmessstreifen

- Temperatur

- Neigen

- Drehmoment

- Vibration

- Zubehör Elektroakustikanwendung

- Künstliches Ohr

- Künstlicher Mund

- Knochenleitung

- Datenerfassung

- HATS Kopf-Torso-Simulator

- Mikrofon

- Signalaufbereitung

- Testlösungen

- Zubehör

- Aktoren

- Verbrennungsmotoren

- Betriebsfestigkeit

- eDrive

- Mobile Systeme

- Sensoren für Produktionstests

- Getriebe

- Turbolader

- Akustik

- Anlagen- und Prozessüberwachung

- Elektrische Energie

- Kundenspezifische Sensoren

- NVH

- Zuverlässigkeit

- Smarte Sensoren

- Schwingbelastung

- Virtuelle Tests

- Strukturelle Integrität

- Wägetechnik

- Druckkalibrierung | Sensor | Messumformer

- Richtlinien zur Bestimmung von Kalibrierintervallen

- Kalibrierung oder Reparatur anfordern

- Kalibrierung und Verifizierung

- Vor-Ort-Kalibrierung (Deutschland)

- Kalibrierung von Schallpegelmessern

- Kalibrierung von Mikrofone und Vorverstärker

- Kalibrierung von Beschleunigungsmessern

- Kalibrierung von Schallpegelmessern (Deutschland)

- Kalibrierung von Analysegeräten

- Eichen von Schallpegelmesser (Österreich)

- Kalibrierung von Lärmdosimetern

- Kalibrierung von Schallkalibrator und Pistonphon

- Kalibrierung des Referenzgeräts

- Kalibrierung Plus Vertrag

arrow_back_ios

See All Durability

See All Reliability

See All Analyse Simulation

See All DAQ

See All API Treiber

See All Dienstprogramm

See All Vibrationskontrolle

See All Kalibrierung

See All DAQ

See All Handheld

See All Industriell

See All Power Analyzer

See All Signalaufbereiter

See All Akustik

See All Strom und Spannung

See All Weg

See All Kraft

See All Wägezellen

See All Mehrkomponenten

See All Druck

See All Dehnung

See All Dehnungsmessstreifen

See All Temperatur

See All Neigen

See All Drehmoment

See All Vibration

See All Zubehör

See All Steuerungen

See All Messerreger

See All Modalerreger

See All Leistungsverstärker

See All Shaker Systeme

See All Testlösungen

See All Aktoren

See All Verbrennungsmotoren

See All Betriebsfestigkeit

See All eDrive

See All Sensoren für Produktionstests

See All Getriebe

See All Turbolader

See All Schulungskurse

See All Akustik

See All Anlagen- und Prozessüberwachung

See All Elektrische Energie

See All Kundenspezifische Sensoren

See All NVH

See All Smarte Sensoren

See All Schwingbelastung

See All Strukturelle Integrität

See All Automobil & Bodentransport

See All Druckkalibrierung | Sensor | Messumformer

See All Kalibrierung oder Reparatur anfordern

See All Kalibrierung und Verifizierung

See All Kalibrierung Plus Vertrag

See All Brüel & Kjær Support

Main Menu

- Weibull++ - NEW TEST (DE)

- Weibull++ - NEW TEST (DE)

- BlockSim - New Test (DE)

- BlockSim - New Test (DE)

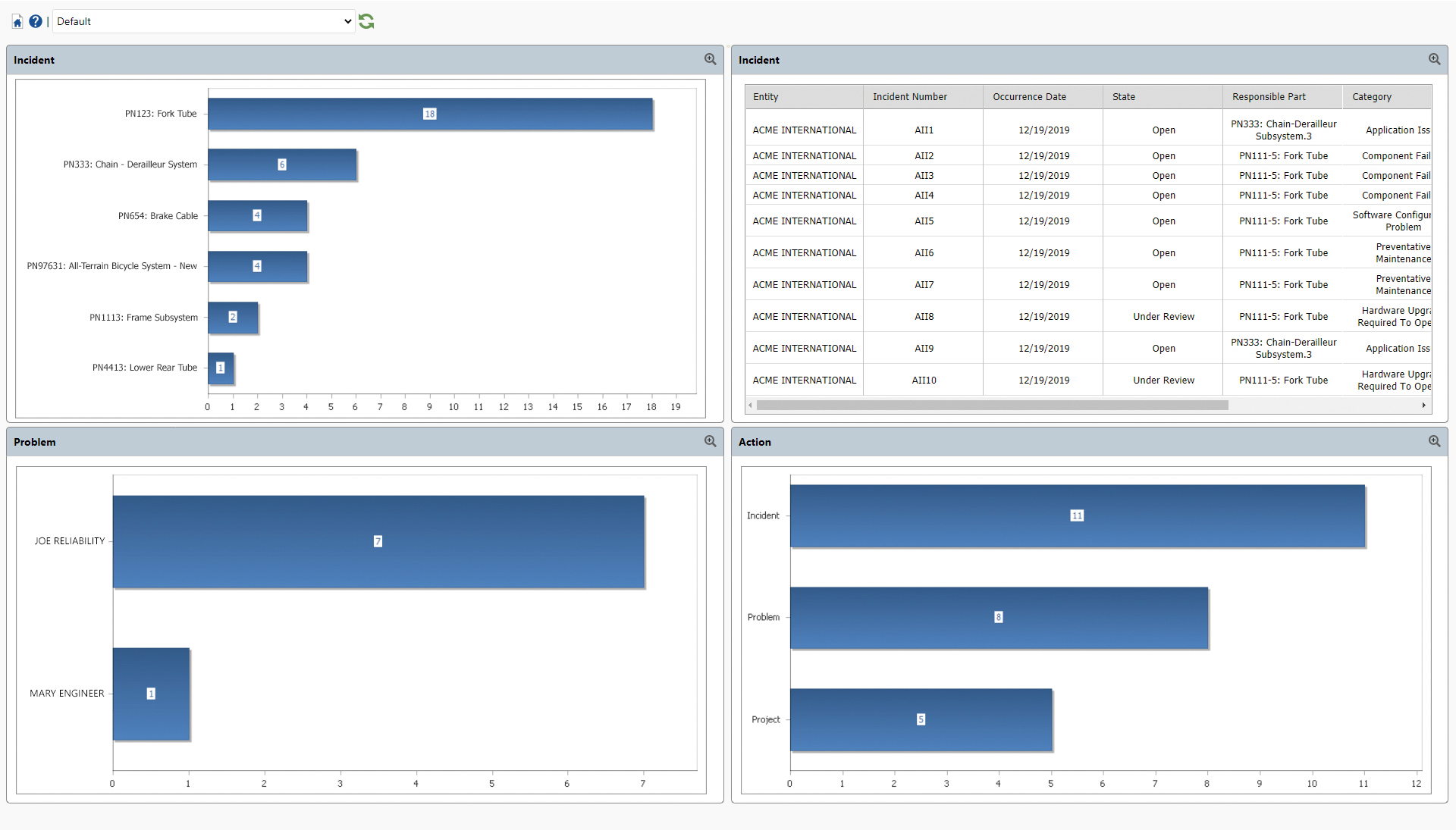

- XFRACAS - New Test (DE)

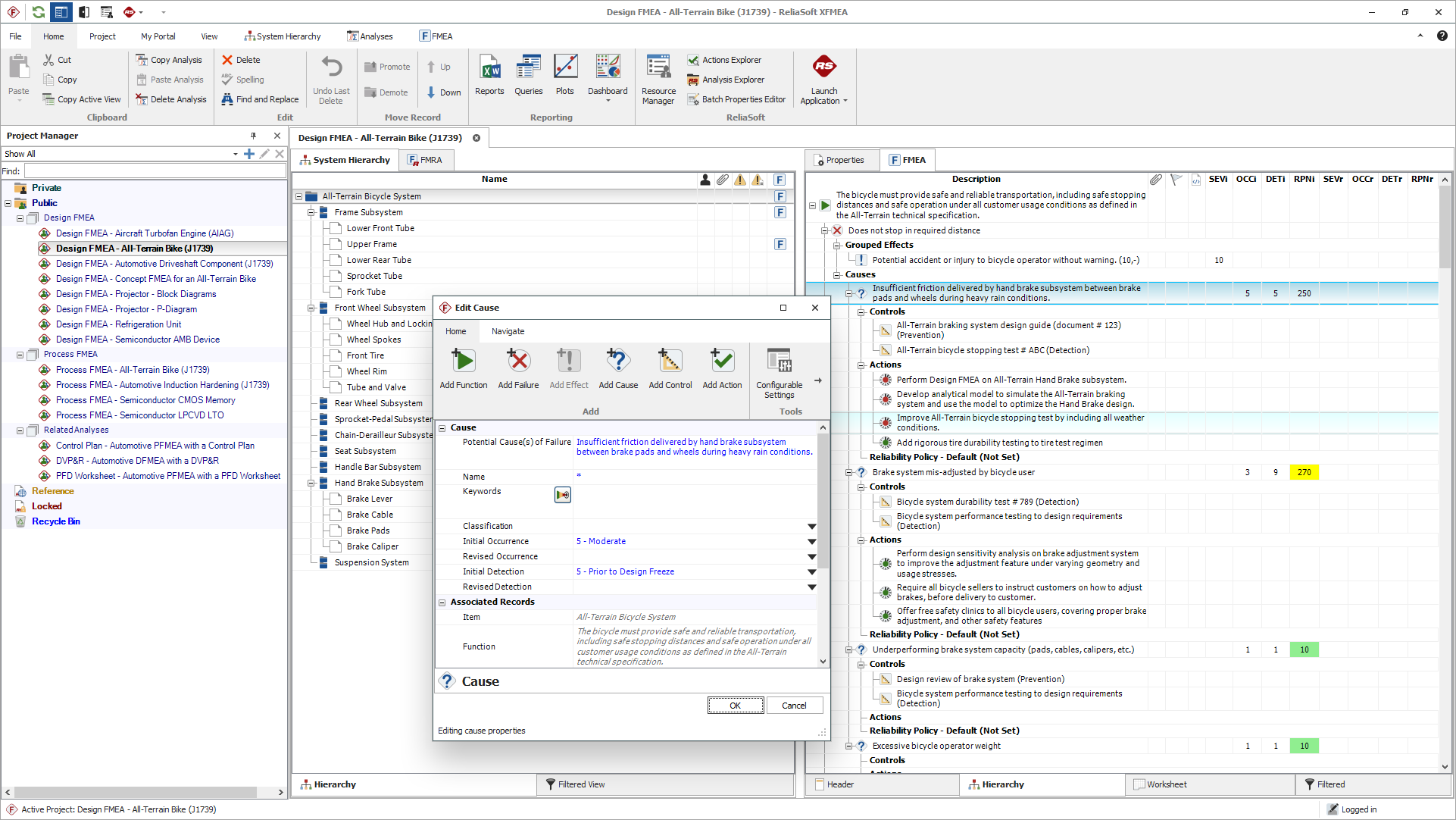

- XFMEA - New Test (DE)

- XFMEA - New Test (DE)

- RCM++ - New Test (DE)

- RCM++ - New Test (DE)

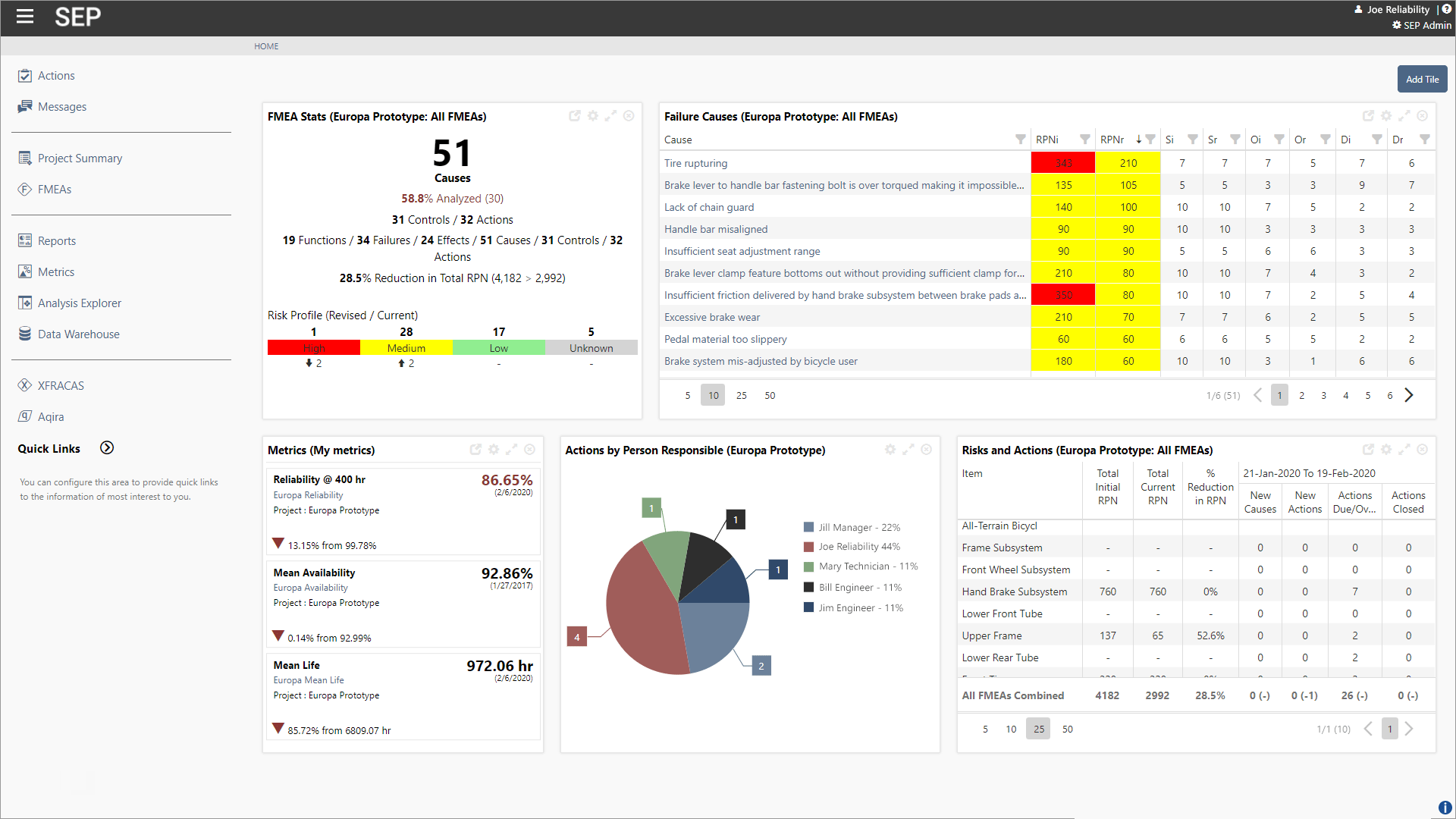

- SEP - New Test (DE)

- SEP - New Test (DE)

- Lambda Predict - New Test (DE)

- Lambda Predict - New Test (DE)

- Weibull++ - Accelerated Life Testing Module - New Test (DE)

- Weibull++ - Reliability Growth Module - New Test (DE)

- BlockSim - Event Analysis Module - New Test (DE)

- MPC - New Test (DE)

- Schwingungsregelungssoftware

- Zufällig

- Klassisch Schock

- Replikation von Zeitkurven

- Sine-on-random

- Random-on-random

- Synthese des Schockantwortspektrums (SRS)

- Mehrkanal-Systeme

- Einkanalige Systeme

- Piezoelektrische Paceline

- Einpress-Controller

- Verstärker mit Display

- Eichfähig

- Zubehör

- Mikrofonkapseln

- Mikrofon-Vorverstärker

- Mikrofon-Sets

- Hydrophone

- Schallquellen

- Kalibratoren

- Spezielle Mikrofone

- Zubehör

- Ladungs-Beschleunigungssensoren

- CCLD-Beschleunigungsmesser

- Kraftaufnehmer

- Referenz-Beschleunigungssensoren

- Drehzahlsensoren

- Kalibratoren

- Optische Beschleunigungsmesser

- Zubehör

- Abgekündigt

- DC Statische Zentriereinheit

- Stromversorgung für den Feldeinsatz

- Kabel

- Drehzapfen

- Aufstellbügel für Schwingerreger

- Akustik und Schwingungen

- Anlagen- und Prozessüberwachung

- Datenakquisition

- Elektrische Maschinen und Leistungselektronik

- Ermüdungs- und Lebensdaueranalysen

- Mechanisches Testen und Prüfen

- Wägetechnik

- Elektroakustik

- Umgebungslärm

- Identifizierung der Lärmquelle

- Produkt-Lärm

- Rampengeräuschprüfung

- Zertifizierung statischer Motorengeräusche

- Schallleistung und Schalldruck

- Flugzertifizierung

- Akustische Materialprüfung

- Vorbeifahrgeräusche

- Industrielle Prozesskontrolle

- Strukturüberwachung

- Produktionsprüfung und Qualitätssicherung

- Maschinenanalyse und -diagnose

- Strukturüberwachung

- Prüfungen von Schaltanlagen

- Hochspannung

- Erprobung von Antriebssträngen

- Batterieprüfung

- Elektrische Maschinenprüfung | Powertrain Testing | HBM

- Einführung in die Messung elektrischer Leistung bei transienten Vorgängen

- Transformator-Ersatzschaltbild | HBM

- Aktuelle Nulltests

- Netzprüfung | Schaltanlagenprüfung | Lösungen | HBM

- Tests im Antriebsstrang

- Schaltgeräte-Tests

- OEM Custom Sensorbaugruppen für eBikes

- OEM kundenspezifische Sensorbaugruppen für die Agrarindustrie

- Kundenspezifische OEM-Sensor-Baugruppen für medizinische Anwendungen

- Kundenspezifische Sensorbaugruppen für Robotic OEM

- Dauerhaftigkeitsprüfung - Ermüdungsprüfung

- Schock- und Falltests

- Verpackungsprüfung / Transportschwingungen

- Umweltstress-Screening - ESS

- Mechanische Satellitenqualifikation

- Buzz, Squeak und Rattle (BSR)

- Batterieprüfung für Elektro- und Hybridfahrzeuge

arrow_back_ios

See All Aqira

See All nCode Viewer (DE)

See All Weibull++ - NEW TEST (DE)

See All Weibull++ - NEW TEST (DE)

See All BlockSim - New Test (DE)

See All BlockSim - New Test (DE)

See All XFRACAS - New Test (DE)

See All XFMEA - New Test (DE)

See All XFMEA - New Test (DE)

See All RCM++ - New Test (DE)

See All RCM++ - New Test (DE)

See All SEP - New Test (DE)

See All SEP - New Test (DE)

See All Lambda Predict - New Test (DE)

See All Lambda Predict - New Test (DE)

See All MPC - New Test (DE)

See All nCode - Durability and Fatigue Analysis

See All ReliaSoft - Reliability Analysis and Management

See All API

See All Elektroakustik

See All Umgebungslärm

See All Identifizierung der Lärmquelle

See All Produkt-Lärm

See All Schallleistung und Schalldruck

See All Vorbeifahrgeräusche

See All Strukturüberwachung

See All Produktionsprüfung und Qualitätssicherung

See All Maschinenanalyse und -diagnose

See All Strukturüberwachung

See All Batterieprüfung

See All Einführung in die Messung elektrischer Leistung bei transienten Vorgängen

See All Transformator-Ersatzschaltbild | HBM

See All Strukturelle Dynamik

See All Prüfung der Materialeigenschaften

See All Sicherstellung der strukturellen Integrität von Leichtbaustrukturen

See All Elektrifizierung von Fahrzeugen

See All Seiten, die nicht migriert wurden

See All Software-Lizenzverwaltung

Main Menu

- Prüfung von Telefon-Headsets und -Hörern

- Prüfung von Freisprecheinrichtungen

- Kopfhörer-Tests

- Hörgerätetest

- Lautsprecher-Tests

- Testen von Smart Speakern

- Akustische Holografie

- Akustische Entfernungsmessung unter Wasser

- Akustische Tests im Windkanal - Luft- und Raumfahrt

- Windkanaltests für Autos

- Beamforming

- Fragen

- Identifizierung der Lärmquelle eines Überflugs

- Echtzeit-Identifizierung der Geräuschquelle mit akustischer Kamera

- Schallintensitätskartierung

- Sphärische Strahlformung

- Eisenbahn-Monitoring

- Tunnelüberwachung mit Faser-Bragg-Sensoren

- Monitoring-Lösungen für zivile Infrastrukturen

- Überwachungslösungen für Windturbinen

- Überwachungslösungen für die Öl- und Gasindustrie

- Überwachungslösungen für Eisenbahnen

- Überwachungslösungen für den Tiefbau

- Verfügbare Monitoring Services

- Fundamentüberwachung mit Dehnungsmessstreifen

- Auftragsanalyse

- Maschinendiagnose

- Gesundheits- und Nutzungsüberwachungssysteme (HUMS)

- Gasturbinenprüfung

- Fragen zur maschinellen Analyse

- Tunnel-Monitoring mit optischen Sensoren

- Monitoring-Lösungen für zivile Infrastrukturen

- Überwachungslösungen für Windturbinen

- Überwachungslösungen für die Öl- und Gasindustrie

- Überwachungslösungen für den Schienenverkehr

- Überwachungslösungen für das Bauwesen

- Verfügbare Monitoring-Services

- Fundamentüberwachung mit Dehnungsmessstreifen

- Mechanische Batterieprüfung mit Kraftsensoren

- Batterietests in der eMobilität

- Batterieprüfung in der Elektromobilität

- Mechanische Batterieprüfung mit Kraftsensoren

- Betriebsablenkungsformen (ODS)

- Klassische Modalanalyse

- Bodenvibrationstest (GVT)

- Operative Modalanalyse (OMA)

- Strukturelle Gesundheitsüberwachung (SHM)

- Test-FEA-Integration

- Schock-Reaktions-Spektrum (SRS)

- Strukturdynamische Systeme

- Fragen zur Strukturdynamik?

- Experimentelle Eigenspannungsanalyse mit dem Loch-Dril

- QuantumX Integration in ZwickRoell Prüfmaschine

- Eigenspannungen | Eigenspannungsmessung

- Elektrifizierung - Statistische Aspekte und Zuverlässigkeit (NEU)

- Elektrifizierung - Elektrische und signalverarbeitende Aspekte (NEU)

- Elektrifizierung — Mechanische und Haltbarkeitsaspekte (NEU)

- Elektrifizierung (NEU) - Auslegung und Prüfung der Lebensdauer von Strukturen für Elektrofahrzeuge

- "Elektrifizierung (NEU) - Elektrifizierung: Gewährleistung der Betriebsfestigkeit, Zuverlässigkeit und Leistung von Elektrofahrzeugen"

- Elektrifizierung (NEU) - Elektrische und Signal Nachbearbeitungstechniken für die Wechselstromanalyse in Elektrofahrzeugen

- Elektrifizierung (NEU) - Anwendung statistischer und Zuverlässigkeitstechniken zur Bestimmung der Batterielebensdauer in Elektrofahrzeugen