arrow_back_ios

Main Menu

arrow_back_ios

Main Menu

- Mechanical & structural DAQ systems

- Sound & Vibration DAQ systems

- Industrial electronics

- Simulator Systems

- Electric power analyzers

- S&V Handheld devices

- Wireless DAQ Systems

- DAQ

- Drivers API

- nCode - Durability and Fatigue Analysis

- ReliaSoft - Reliability Analysis and Management

- Test Data Management

- Utility

- Vibration Control

- Inertial Sensor Software

- Test Data Management

- Acoustic

- Current / voltage

- Displacement

- Exciters

- Force

- Inertial Sensors

- Load cells

- Multi Component

- Pressure

- Smart Sensors with IO-Link interface

- Strain

- Temperature

- Tilt

- Torque

- Vibration

- OEM Custom Sensors

- Calibration Services for Transducers

- Calibration Services for Handheld Instruments

- Calibration Services for Instruments & DAQ

- On-Site Calibration

- Resources

- Articles

- Case Studies

- Recorded Webinars

- Presentations

- Primers and Handbooks

- Videos

- Whitepapers

- Search all resources

- Acoustics

- Data Acquisition & Analysis

- Durability & Fatigue

- Electric Power Testing

- Industrial Process Automation

- Machine automation control and navigation

- NVH

- Reliability

- Smart Sensors

- Structural Health Monitoring

- Vibration

- Virtual Testing

- Weighing

- Road Load Data Acquisition

arrow_back_ios

Main Menu

- QuantumX

- SomatXR

- MGCplus

- Optical Interrogators

- CANHEAD

- eDAQ

- Strain Gauge precision instrument

- Bridge calibration units

- GenHS

- LAN-XI

- Fusion-LN

- CCLD (IEPE) signal conditioner

- Charge signal conditioner

- Microphone signal conditioner

- NEXUS

- Microphone calibration system

- Vibration transducer calibration system

- Sound level meter calibration system

- Accessories for signal conditioner

- Accessories for calibration systems

- Multi channel amplifier

- Single channel amplifier and amplifier with display

- Weighing indicators

- Weighing electronics

- Accessories for industrial electronics

- eDrive power analyzer

- eDrive Package - Remote Probe based

- eGrid power analyzer

- GenHS

- Accessories for power analyzer and GenHS

- BK Connect / PULSE

- catman Enterprise

- catmanEasy AP

- Software Downloads for Perception / Genesis HighSpeed

- Tescia

- Catman data acquisition software

- Thousands of Channels at a Glance

- Perception – High speed data acquisition software

- Drivers for compatibility with third party software

- ReliaSoft BlockSim

- ReliaSoft Cloud

- ReliaSoft Lambda Predict

- ReliaSoft MPC

- ReliaSoft Product Suites

- ReliaSoft RCM++

- ReliaSoft XFMEA

- ReliaSoft XFRACAS

- ReliaSoft Weibull++

- Classical Shock

- Random

- Random-On-Random

- Shock Response Spectrum Synthesis

- Sine-On-Random

- Time Waveform Replication

- Vibration Control Software

- Microphone sets

- Cartridges

- Reference microphones

- Special microphones

- Acoustic material testing kits

- Acoustic calibrators

- Hydrophones

- Microphone Pre-amplifiers

- Sound Sources

- Accessories for acoustic transducers

- Fiber Optic Technology

- Inductive technology

- Strain gauge technology

- Accessories for displacement sensors

- Inertial Measurement Units (IMU)

- Vertical Reference Units (VRU)

- Attitude and Heading Reference Systems (AHRS)

- Inertial Navigation Systems (INS)

- Inertial Sensor Accessories

- Bending / beam

- Canister

- Compression

- Single Point

- Tension

- Weighing modules

- Digital load cells

- Accessories for load cells

- Strain gauges for experimental testing

- Fiber optical strain gauges

- Strain gauges for transducer manufacturing (OEM)

- Strain sensors

- Accessories for strain gauges

- CCLD (IEPE) accelerometer

- Charge accelerometer

- Variable Capacitance (VC) MEMS

- Fiber Optic Accelerometer

- Force transducers

- Reference accelerometer

- Impulse hammers / impedance heads

- Tachometer probes

- Vibration calibrators

- Cables

- Accessories

- Force - OEM custom sensors

- Torque - OEM custom sensors

- Load - OEM custom sensors

- Multi-Axis - OEM custom Sensors

- Pressure - OEM custom sensors

- HATS (Head and torso simulator)

- Artificial Ear

- Electroacoustic hardware

- Bone conduction

- Electroacoustic software

- Pinnae

- Accessories for electroacoustic application

- Accessories

- Actuators

- Combustion Engines

- Durability

- eDrive

- Mobile Systems

- Production Testing Sensors

- Transmission Gearboxes

- Turbo Charger

- Force Calibration

- Torque Calibration

- Microphones & Preamplifiers Calibration

- Accelerometers Calibration

- Pressure Calibration

- Displacement Sensor Calibration

- Sound Level Meter Calibration

- Sound Calibrator & Pistonphone Calibration

- Vibration Meter Calibration

- Vibration Calibrator Calibration

- Noise Dosimeter Calibration

- QuantumX Calibration

- Genesis HighSpeed Calibration

- Somat Calibration

- Industrial Electronics Calibration

- LAN-XI Calibration

- Guidelines on Calibration Intervals

- Certificate Samples

- Interactive Calibration Certificate

- Download of Calibration Certificates

- Acoustics and Vibration

- Asset & Process Monitoring

- Data Acquisiton

- Electric Power Testing

- Fatigue and Durability Analysis

- Mechanical Test

- Reliability

- Weighing

- Electroacoustics

- Noise Source Identification

- Handheld S&V measurements

- Sound Power and Sound Pressure

- Noise Certification

- Acoustic Material Testing

- Structural Durability and Fatigue Testing

- Durability Simulation & Analysis

- Material Fatigue Characterisation

- Electrical Devices Testing

- Electrical Systems Testing

- Grid Testing

- High-Voltage Testing

- End of Line Durability Testing

- Vibration Testing with Electrodynamic Shakers

- Structural Dynamics

- Machine Analysis and Diagnostics

- Troubleshooting Analyser

- Process Weighing

- Sorting and Batching Solutions

- Scale Manufacturing Solutions

- Vehicle Scale Solutions

- Filling, Dosing and Checkweighing Control

arrow_back_ios

Main Menu

- Measurement modules

- Input/output modules

- Data recorder / Gateways

- Accessories for QuantumX

- Measurement modules

- Housing

- Communication processor

- Amplifier modules

- Connection boards

- Special function modules

- Accessories for MGCplus

- Binaural Audio

- Outdoor microphones

- Probe Microphones

- Sound intensity probes

- Surface microphone

- Array microphones

- Other special microphones

- Microphones for production line test

- Probe microphones

- Microphone Cables

- Tripods

- Microphone booms

- Microphone adapters

- Electrostatic actuators

- Microphone windscreen

- Nose cones

- Microphone holders

- Other accessories for acoustic transducers

- Microphones outdoor protection

- Rod end bearings

- Tensile load introductions

- Thrust pieces and load buttons

- Cables and connectors

- Screw sets

- Load bases / Tensile compressive adapters

- Measurement cables

- Ground cables

- Thrust pieces

- Bearings

- Load feet

- Base plates

- Knuckle eyes

- Adapters

- Mounting aids and others

- Adhesives

- Protective coatings

- Cleaning material

- SG Kits

- Solder terminals

- Other strain gauge accessories

- Cables

- ZeroPoint Balancing

- TCS Balancing

- TC0 Balancing

- Magnets

- Mounting clips/bases

- Studs, screws and washers

- Adhesives/Tools

- Adapters

- Mechanical filters

- Other accessories

- High-Force LDS Shakers

- Medium-Force LDS Shakers

- Low-Force LDS Shakers

- Permanent Magnet Shakers

- Shaker Equipment / Slip Tables

- Testing Of Hands-Free Devices

- Smart Speaker Testing

- Speaker Testing

- Hearing Aid Testing

- Headphone Testing

- Soundbar Testing

- Telephone Headset And Handset Testing

- Acoustic Holography

- Acoustic Signature Management

- Underwater Acoustic Ranging

- Wind Tunnel Acoustic Testing – Aerospace

- Wind Tunnel Testing For Cars

- Beamforming

- Flyover Noise Source Identification

- Real-Time Noise Source Identification With Acoustic Camera

- Sound Intensity Mapping

- Spherical Beamforming

- Product Noise

- Messung der Unrundheit von Eisenbahnrädern

- On-Board Measurement

- Pantograph and Overhead Lines Monitoring

- Wayside Train Monitoring & Measurement

- Shock and Drop Testing

- Environmental Stress Screening - ESS

- Package Testing

- Buzz, Squeak and Rattle (BSR)

- Mechanical Satellite Qualification - Shaker Testing

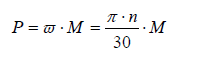

(1)

where M is torque and n rotational speed. Torque is given by

(1)

where M is torque and n rotational speed. Torque is given by

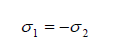

(3)

Since in this case, the center of Mohr's circle is positioned in the origin of its coordinate system, the shear stresses correspond to the absolute value of the principal normal stresses. It follows that

(3)

Since in this case, the center of Mohr's circle is positioned in the origin of its coordinate system, the shear stresses correspond to the absolute value of the principal normal stresses. It follows that

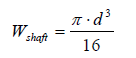

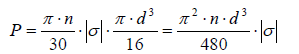

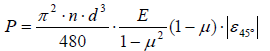

(5)

assuming that the input shaft is a cylindrical solid shaft. Resulting from (1) … (5) power is given by

(5)

assuming that the input shaft is a cylindrical solid shaft. Resulting from (1) … (5) power is given by

(6)

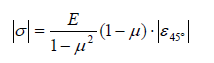

The normal stress of a torsion shaft is:

(6)

The normal stress of a torsion shaft is:

(7)

where E is the modulus of elasticity, μ Poisson's ratio and

(7)

where E is the modulus of elasticity, μ Poisson's ratio and  (8)

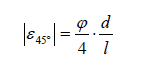

Example A: Determining strain

(8)

Example A: Determining strain  (9)

The single errors to be allowed for result from the tolerances of the input drive's diameter d and length l as well as the measurement error φ, see table 1.

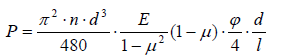

Considering (8) and (9) the power determined by measuring the torsion angle is:

(9)

The single errors to be allowed for result from the tolerances of the input drive's diameter d and length l as well as the measurement error φ, see table 1.

Considering (8) and (9) the power determined by measuring the torsion angle is:

(10)

(10)