arrow_back_ios

Main Menu

arrow_back_ios

Main Menu

- Sistemas DAQ mecânicos e estruturais

- Sistemas DAQ de som e vibração

- Eletrônica industrial

- Simulator Systems

- Analisador de potência elétrica

- Dispositivos portáteis S&V

- Sistemas DAQ sem fio

- DAQ

- Drivers API

- nCode - Durability and Fatigue Analysis

- ReliaSoft - Reliability Analysis and Management

- Test Data Management

- Utility

- Vibration Control

- Inertial Sensor Software

- Sensor Finder

- Acoustic

- Current / voltage

- Displacement

- Excitadores

- Force

- Sensores inerciais

- Células de carga

- Multi Component

- Pressure

- Sensores inteligentes com interface IO-Link

- Strain

- Optical Temperature Sensors

- Tilt Sensors

- Torque

- Vibration

- OEM Custom Sensors

- Calibration Services for Transducers

- Calibration Services for Handheld Instruments

- Calibration Services for Instruments & DAQ

- On-Site Calibration

- Resources

- Articles

- Case Studies

- Recorded Webinars

- Primers and Handbooks

- Videos

- Whitepapers

- Search all resources

- Acoustics

- Data Acquisition & Analysis

- Durability & Fatigue

- Electric Power Testing

- Industrial Process Automation

- Machine automation control and navigation

- NVH

- Reliability

- Smart Sensors

- Structural Health Monitoring

- Vibration

- Virtual Testing

- Weighing

- Road Load Data Acquisition

arrow_back_ios

Main Menu

- QuantumX

- SomatXR

- MGCplus

- Interrogadores ópticos

- CANHEAD

- eDAQ

- Instrumento de precisão para extensômetro

- Unidades de calibração de pontes

- GenHS

- LAN-XI

- Fusion-LN

- Condicionador de sinais CCLD (IEPE)

- Condicionador de sinais de carga

- Condicionador de sinais de microfone

- NEXUS

- Sistema de calibração de microfones

- Sistema de calibração de transdutores de vibração

- Sistema de calibração para medidores de nível de som

- Acessórios para condicionador de sinais

- Acessórios para sistemas de calibração

- Sistema de multi canais

- Amplificador de canal único e amplificador com display

- Indicadores de pesagem

- Eletrônica de pesagem

- Acessórios para eletrônica industrial

- Pacote eDrive

- eDrive Package - Remote Probe based

- Pacote eGrid

- GenHS

- Acessórios para analisador de potência e GenHS

- Medidores de nível de som

- Medidores de vibração

- Software portátil

- Acessórios para dispositivos portáteis S&V

- BK Connect / PULSE

- Tescia

- Catman data acquisition software

- Thousands of Channels at a Glance

- Perception – High speed data acquisition software

- Drivers for compatibility with third party software

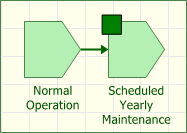

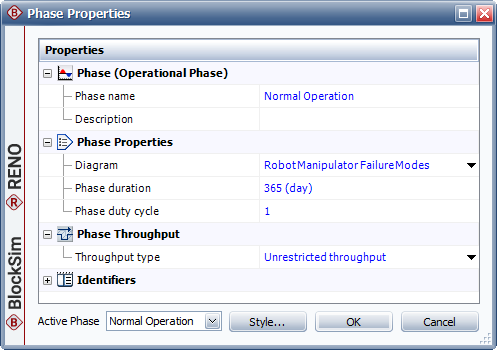

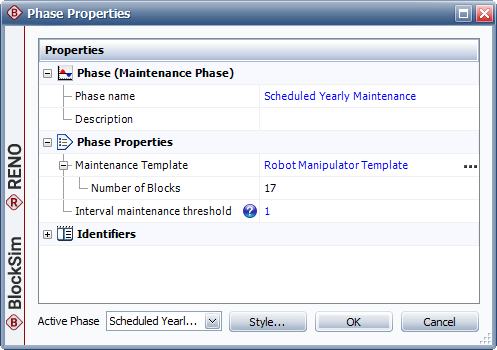

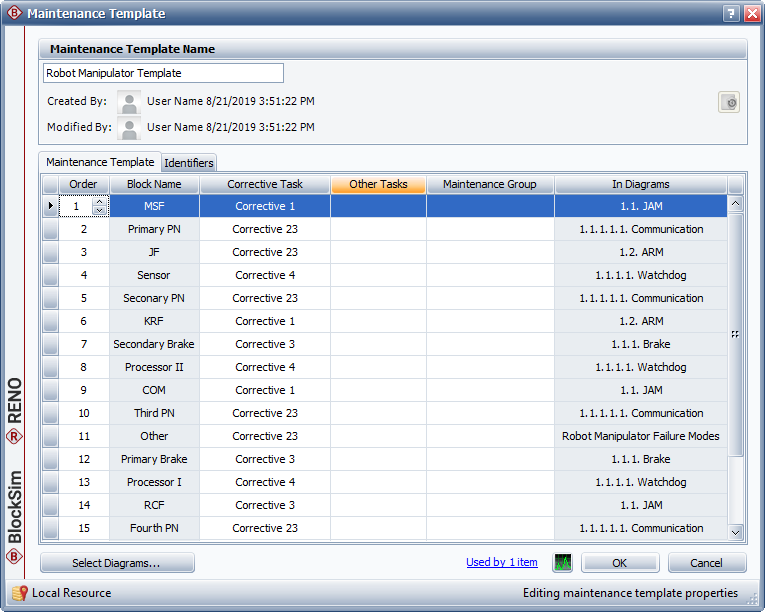

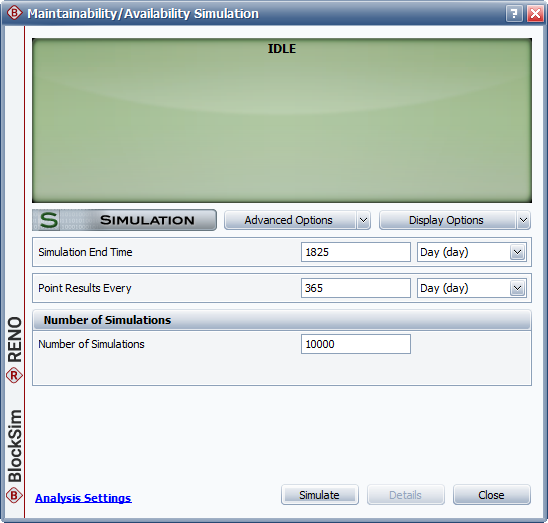

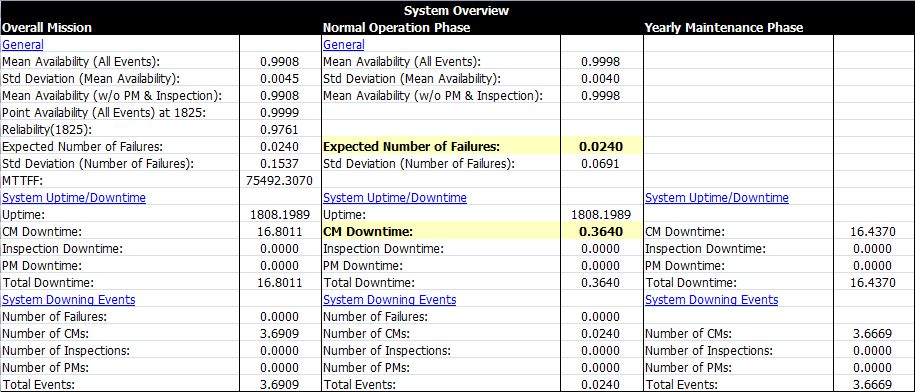

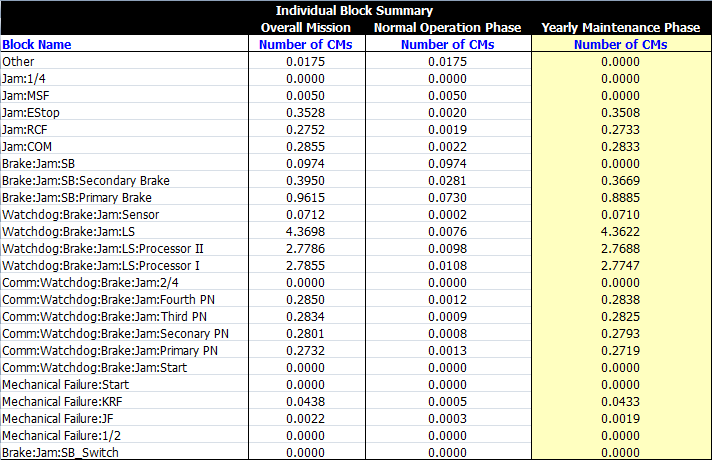

- ReliaSoft BlockSim

- ReliaSoft Cloud

- ReliaSoft Lambda Predict

- ReliaSoft MPC

- ReliaSoft Product Suites

- ReliaSoft RCM++

- ReliaSoft XFMEA

- ReliaSoft XFRACAS

- ReliaSoft Weibull++

- Classical Shock

- Random

- Random-On-Random

- Shock Response Spectrum Synthesis

- Sine-On-Random

- Time Waveform Replication

- Vibration Control Software

- Microphone sets

- Cartridges

- Microfones de referência

- Microfones especiais

- Kits para teste de materiais acústicos

- Calibradores acústicos

- Hidrofones

- Pré-amplificadores para microfone

- Fontes de som

- Acessórios para transdutores acústicos

- Tecnologia de fibra ótica

- Tecnologia indutiva

- Tecnologia de strain gauge

- Acessórios para sensores de deslocamento

- Excitadores de medição

- Excitadores modais

- Accessories

- Amplificador de potência

- Acessórios para equipamento de teste de vibração

- Inertial Measurement Units (IMU)

- Unidades de referência vertical (VRU)

- Sistemas de referência de atitude e rumo (AHRS)

- Sistemas de navegação inercial (INS)

- Acessórios para sensor inercial

- Bending / beam

- Canister

- Compression

- Single Point

- Tension

- Módulos de pesagem

- Células de carga digitais

- Acessórios para células de carga

- Testagem experimental

- Fibra ótica

- Fabricação de transdutores (OEM)

- Sensores de deformação

- Acessórios para extensômetros

- Acelerômetro CLLD (IEPE)

- Acelerômetro de carga

- Capacitância variável (VC) MEMS

- Acelerômetro de fibra ótica

- Transdutores de força

- Acelerômetro de referência

- Martelos de impacto / cabeçotes de impedância

- Sonda de tacômetro

- Calibradores de vibração

- Cabos

- Accessories

- Force - OEM custom sensors

- Torque - OEM custom sensors

- Load - OEM custom sensors

- Multi-Axis - OEM custom Sensors

- Pressure - OEM custom sensors

- HATS (Simulador para cabeça e torso)

- Orelha artificial

- Hardware eletroacústico

- Condução óssea

- Software eletroacústico

- Pavilhões auriculares

- Acessórios para aplicação eletroacústica

- Accessories

- Actuators

- Combustion Engines

- Durability

- eDrive

- Mobile Systems

- Production Testing Sensors

- Transmission Gearboxes

- Turbo Charger

- Force Calibration

- Torque Calibration

- Microphones & Preamplifiers Calibration

- Accelerometers Calibration

- Pressure Calibration

- Displacement Sensor Calibration

- Sound Level Meter Calibration

- Sound Calibrator & Pistonphone Calibration

- Vibration Meter Calibration

- Vibration Calibrator Calibration

- Noise Dosimeter Calibration

- QuantumX Calibration

- Genesis HighSpeed Calibration

- Somat Calibration

- Industrial Electronics Calibration

- LAN-XI Calibration

- Guidelines on Calibration Intervals

- Certificate Samples

- Interactive Calibration Certificate

- Download of Calibration Certificates

- Acoustics and Vibration

- Asset & Process Monitoring

- Data Acquisiton

- Electric Power Testing

- Fatigue and Durability Analysis

- Mechanical Test

- Reliability

- Weighing

- Electroacoustics

- Noise Source Identification

- Handheld S&V measurements

- Sound Power and Sound Pressure

- Noise Certification

- Acoustic Material Testing

- Structural Durability and Fatigue Testing

- Durability Simulation & Analysis

- Material Fatigue Characterisation

- Electrical Devices Testing

- Electrical Systems Testing

- Grid Testing

- High-Voltage Testing

- End of Line Durability Testing

- Vibration Testing with Electrodynamic Shakers

- Structural Dynamics

- Machine Analysis and Diagnostics

- Troubleshooting Analyser

- Naval Certification and Sea-Trials

- Process Weighing

- Sorting and Batching Solutions

- Scale Manufacturing Solutions

- Vehicle Scale Solutions

- Filling, Dosing and Checkweighing Control

arrow_back_ios

Main Menu

- Módulos de medição

- Módulos de entrada/saída

- Gravador de dados / portas

- Acessórios para QuantumX

- Módulos de medição

- Carcaça

- Processador de comunicação

- Módulos de amplificador

- Placas de conexão

- Módulos de funções especiais

- Acessórios para MGCplus

- Áudio binaural

- Microfones para exteriores

- Probe Microphones

- Sondas para intensidade sonora

- Microfone de superfície

- Conjunto de microfones

- Outro microfone especial

- Microfones para teste em linha de produção

- Microfone de sonda

- Cabos de microfone

- Tripés

- Hastes de microfone

- Adaptadores de microfone

- Atuadores eletrostáticos

- Pára-brisa do microfone

- Cones de nariz

- Suportes para microfone

- Outros acessórios para transdutores acústicos

- Proteção para microfones externos

- Unidade de centralização estática DC

- Fontes de alimentação em campo

- Pinhões

- Suporte de excitador

- Cabos

- Stinger

- Cabeças de articulação

- Introdução às cargas de tração (de acordo com ISO 376)

- Elementos de pressão e botões de carga

- Cabos e conectores

- Conjuntos de parafusos

- Base de carga / Adaptadores de tração e compressão

- Cabos de medição

- Cabos de aterramento

- Elementos de pressão

- Rolamentos

- Carga linear

- Placas de base

- Olhais articulados

- Adaptadores

- Acessórios de montagem e outros

- Adesivos

- Revestimentos de proteção

- Material de limpeza

- Kits de SG

- Terminal de solda

- Outros acessórios de extensômetros

- Cabos

- Compensação ponto zero

- Compensação TCS

- Compensação TC0

- Ímãs

- Clipes/bases de montagem

- Pinos, parafusos e arruelas

- Adesivos/ferramentas

- Adaptadores

- Filtros mecânicos

- Outros acessórios

- Agitadores LDS de alta potência

- Agitadores LDS de média potência

- Agitadores LDS de baixa potência

- Agitadores magnéticos permanentes

- Equipamento agitador / mesas deslizantes

- Testing Of Hands-Free Devices

- Smart Speaker Testing

- Speaker Testing

- Hearing Aid Testing

- Headphone Testing

- Soundbar Testing

- Telephone Headset And Handset Testing

- Acoustic Holography

- Acoustic Signature Management

- Underwater Acoustic Ranging

- Wind Tunnel Acoustic Testing – Aerospace

- Wind Tunnel Testing For Cars

- Beamforming

- Flyover Noise Source Identification

- Real-Time Noise Source Identification With Acoustic Camera

- Sound Intensity Mapping

- Spherical Beamforming

- Product Noise

- HighVoltage HighPower Switchgear Tests

- Transformer Testing

- Current Zero Testing

- Circuit Breaker Testing

- Messung der Unrundheit von Eisenbahnrädern

- On-Board Measurement

- Pantograph and Overhead Lines Monitoring

- Wayside Train Monitoring & Measurement

- Shock and Drop Testing

- Environmental Stress Screening - ESS

- Package Testing

- Buzz, Squeak and Rattle (BSR)

- Mechanical Satellite Qualification - Shaker Testing